Applying the information-value loop

By now you can realize that you should always think of the following when starting an IoT project:

- 💸 Defining the added value: What does this solution provide in terms of value for the user, the company or the organisation? Without a clear view of this and these end goals, it is a lot more difficult to convince people to spend money on your IoT solution. Having a solid idea of this also helps in making descisions along the way when designing your solution more in depth.

- 🔄 Setting up the information-value loop: Looking at your solution more in depth and moving to your value goals involves thinking about every step in the information-value loop. Making the right choice in each step and aspect should have you asking questions surrouding:

- Features: Does this component have all the features I need? Does it have too many features? Is this battery-powered?

- Budget: Does this component fit into my budget or pricepoint of my total solution? Can I get a cheaper alternative that still has all the features I need but not too many?

- Compatibility: Does this sensor work with this protocol? Can this platform connect this many devices or sensors?

- Support: Is there enough information or are there manuals about this component or platform?

- 📑 Listing how you covered value drivers: Covering each step and aspect of the information-value loop with decisions around features, budget, compatibility, support... is a good start but not enough in the bigger picture of getting an IoT solution to deliver the value it needs. Later on this page we will talk about these value drivers.

These are not all the aspects and questions you should think about surrounding an IoT solution, but certainly the most important ones.

In the following section the first two of these steps are applied to two examples. One with no Cloud involved which uses a smartphone as final platform instead and one which does use a Cloud platform.

A consumer IoT device: your smartphone as the final platform

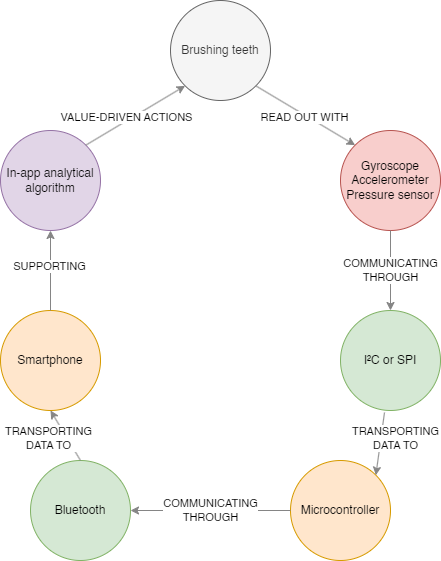

The Oral-B's Genius X smart toothbrush is a consumer IoT device that uses sensors, embedded communication protocols, embedded platforms, regular wireless communication protocols, non-embedded platforms, analytical and intelligence tools to improve the user's oral hygiene by providing information and advice on a smartphone app.

The Oral-B's Genius X smart toothbrush is a consumer IoT device that uses sensors, embedded communication protocols, embedded platforms, regular wireless communication protocols, non-embedded platforms, analytical and intelligence tools to improve the user's oral hygiene by providing information and advice on a smartphone app.

💸 Defining the added value

For users to actually buy and use the Oral-B's Genius X smart toothbrush it has to provide value as an IoT solution, for example through:

- Personalized brushing feedback: The toothbrush can use sensors to detect the pressure, angle, and duration of the user's brushing, and provide real-time feedback and guidance through an app on the user's smartphone.

- Improved brushing habits: The toothbrush can store and analyze the user's brushing data, and provide personalized recommendations and insights to help the user improve their brushing habits.

- Enhanced oral health: The toothbrush app provides advice to adjust the speed, intensity, and mode of the brushing, according to the user's preferences and needs. It can also use sensors to monitor the user's oral health and alert the user of any potential issues or risks.

🔄 Setting up the information-value loop

To actually reach the point where an IoT solution can provide the information and advice to create this value, it must have every aspect of its information-value loop in order. And every aspect must be the result of a well-thought choice about features, budget, compatibility, support, ... of a component or part.

For the Oral-B's Genius X smart toothbrush we can roughly determine the following information-value loop aspects and steps:

- Sensors: The toothbrush has a gyroscope and an accelerometer that detect the position, orientation, and movement of the brush head. It also has a pressure sensor that measures the force applied by the user on the teeth and gums. These sensors generate data about the physical event of brushing the teeth.

- Embedded communication protocols: The toothbrush uses I²C or SPI protocols to communicate between the microcontroller, the sensors, and the Bluetooth module that are part of the embedded system. These protocols enable fast and reliable data transfer within the device.

- Embedded platforms: The toothbrush has a microcontroller that acts as an embedded platform. It can communicate with the sensors and the Bluetooth module using the embedded communication protocols. It can also process and store some of the sensor data locally.

- Regular wireless or wired communication protocols: The toothbrush uses Bluetooth as a regular wireless communication protocol to communicate with the user's smartphone that is not part of the embedded system. Bluetooth enables the toothbrush to send the sensor data to the smartphone app and receive commands or updates from the app.

- Non-embedded platforms: The user's smartphone acts as a non-embedded platform. It receives the sensor data from the toothbrush via Bluetooth and sends it to the analytical and intelligence tools. It also displays the information and insights to the user and allows the user to adjust the settings of the toothbrush.

- Analytical and intelligence tools: The smartphone app uses artificial intelligence and machine learning models to analyze the sensor data and provide information and insights to the user. The app can track the user's brushing habits, identify the areas that need more attention, give feedback and tips, and personalize the brushing experience. For all of this the app uses advanced 3D tracking and AI brushing recognition technology to map out all areas and surfaces on the user's teeth and guide them to their best clean.

Remote truck tracking: the Cloud as the final platform

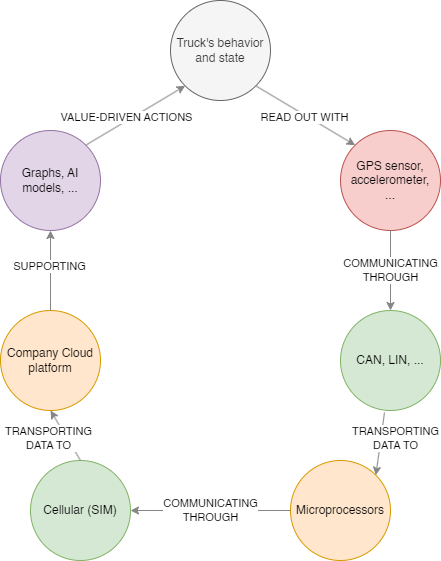

Remote truck tracking is the process of monitoring and managing the movement and status of trucks and their cargo using various technologies. Remote truck tracking can provide many benefits for fleet managers, drivers, customers, and the environment.

Remote truck tracking is the process of monitoring and managing the movement and status of trucks and their cargo using various technologies. Remote truck tracking can provide many benefits for fleet managers, drivers, customers, and the environment.

One example of remote truck tracking is the solution provided by Webfleet Solutions, a company that offers an AI-enhanced vehicle GPS system for actionable insights from fleet data.

💸 Defining the added value

The larger IoT projects are, the larger a company or organisation needs to invest to make it happen. That is also why it is even more important to make it clear what the value provided by the solution will be. This is the case with remote truck tracking as well, for example through:

- Improved efficiency and productivity: Remote truck tracking can help optimize the routes, schedules, and deliveries of the trucks, reducing fuel consumption, travel time, and operational costs. It can also help avoid traffic congestion, road hazards, and weather conditions that may affect the performance of the trucks.

- Enhanced safety and security: Remote truck tracking can help monitor the driver behavior, vehicle condition, and cargo status of the trucks, ensuring the safety and security of the drivers, the vehicles, and the goods. It can also help prevent theft, loss, or damage of the cargo, and provide real-time alerts and assistance in case of emergencies or accidents.

- Increased customer satisfaction: Remote truck tracking can help provide accurate and timely information and updates to the customers, improving their trust and loyalty. It can also help deliver the goods faster, safer, and in better quality, meeting or exceeding the customer expectations.

🔄 Setting up the information-value loop

For an IoT project surrounding remote truck tracking we can roughly determine the following information-value loop aspects:

- Sensors: The trucks have various sensors that monitor the location, speed, fuel level, tire pressure, engine temperature, and cargo weight of the vehicles. These sensors generate data about the physical event of driving the trucks.

- Embedded communication protocols: The trucks use CAN, LIN and other protocols to communicate between the microcontroller, the sensors, and the cellular module that are part of the embedded system. These protocols enable fast and reliable data transfer within the vehicle and can handle critical data exchange between different devices in the vehicle, such as engine control, transmission control, and safety systems.

- Embedded platforms: The trucks can have one or more microprocessors that act as an embedded platform. It can communicate with the sensors and the cellular module using the embedded communication protocols. It can also process and store some of the sensor data locally.

- Regular wireless or wired communication protocols: The trucks use cellular as a regular wireless communication protocol to communicate with the cloud platform that is not part of the embedded system. Cellular is a wireless way of sending and receiving data. It uses small areas of land, called cells, that have towers or antennas. These towers or antennas can talk to your cellphone or other devices that have a SIM card. A SIM card is a small chip that identifies your device and lets you use the cellular network. Cellular networks can let you make calls, send messages, or use the internet.

- Cloud platforms: The cloud platform acts as a non-embedded platform. It receives the sensor data from the trucks via cellular and sends it to the analytical and intelligence tools. It also displays the information and insights to the fleet managers and allows them to adjust the settings of the trucks.

- Analytical and intelligence tools: The cloud platform uses dashboards and machine learning models to analyze the sensor data and provide information and insights to the fleet managers. The platform can track the location, speed, fuel consumption, maintenance needs, and cargo status of the trucks. It can also optimize the routes, schedules, and deliveries of the trucks. It can alert the fleet managers of any issues or anomalies and suggest actions to resolve them.

Expanding: Value drivers 📑

Covering each step and aspect of the information-value loop with decisions around features, budget, compatibility, support... is a good start but not enough in the bigger picture of getting an IoT solution to deliver the value it needs.

There are value drivers that touch on multiple parts and aspects of the information-value loop or even the entire IoT solution. Thinking about these value drivers at the start and along the way is very necessary, as they drive the value forward or can hinder it if badly managed.

The following section lists a number of these drivers. There can of course be more drivers one can think about, but this list should already give a good starting point. Each driver is illustrated with an example from the IoT solution of remote truck tracking.

Magnitude-related value drivers

These are factors that determine the amount of information that informs action.

🗃 Scale: The scale generally determines of how many seperate objects, spaces, ... we acquire data.

For example, in the information-value loop, sensors can create data about multiple trucks in a fleet instead of one truck, and communicate it to a central platform. The platform can aggregate and analyze the data to optimize the routes, fuel consumption, and delivery time of the entire fleet. This can lead to more efficient and profitable actions than if the data was only about one truck.

📏 Scope: The scope generally determines how many dimensions of the state or behaviour are measured.

For example, in the information-value loop, sensors can create data about not only the location, but also the speed, direction, weight, and temperature of a truck. In this way the scope gets larger. This data can be communicated, aggregated, and analyzed to provide more comprehensive and accurate information about the truck's performance, condition, and environment. This can lead to more informed and effective actions than if the data was only about one dimension of the truck.

🔂 Frequency: The frequency generally determines how often a data is collected.

For example, in the information-value loop, sensors can create data about a truck's location every 30 minutes, or do it almost in real-time every 30 seconds. The platform can aggregate and analyze the data to update the information about the truck's progress, traffic, and ETA. This can lead to more timely and responsive actions than if the data was only available once per hour or per day.

Risk-related value drivers

These are factors that determine the probability that information will create value in the manner that is expected.

🦺 Safety: The safety generally determines how well the data is generated and used without causing harm or damage to the physical environment or the people involved. The higher the safety, the lower the risk of accidents or injuries. Without a certain level of safety the entire value of an IoT solution can get wasted.

For example, in the information-value loop, sensors can create data about different aspects of a truck. If there is not enough attention to resistance values in electronics, safely installing and designing the solution it can cause overheating, short-circuiting, or fire hazards, which could otherwise damage the equipment or endanger the workers.

🔐 Security: The security generally determines how well the data and information is protected from unauthorized or malicious access. The higher the security, the lower the risk of information being compromised or misused.

For example, in the information-value loop, sensors can create data about the location of the trucks, and communicate it using encryption and authentication protocols. The platform can aggregate and analyze the data only for authorized users and purposes. This can prevent the information from being stolen or tampered by hackers or competitors, who could otherwise use it to harm the value of the actions.

📶 Reliability: The reliability generally determines how consistently the information is generated and available, unaffected by instability. The higher the reliability, the lower the risk of information being missing or delayed.

For example, in the information-value loop, sensors can create data about the speed, direction, and weight of the trucks, and communicate it using robust and redundant networks. The platform can aggregate and analyze the data without interruption or degradation. This can ensure the information is always present and can support the actions without failure or disruption.

🎯 Accuracy: The accuracy generally determines how well the information reflects the reality of what it represents. The higher the accuracy, the lower the risk of information being erroneous or misleading.

For example, in the information-value loop, sensors can create data about the temperature, pressure, and vibration of the trucks, and communicate it using precise and calibrated measurements. The platform can aggregate and analyze the data using valid and verified methods. This can avoid the information from being inaccurate or incomplete, and can improve the quality and effectiveness of the actions.

Time-related value drivers

These are factors that determine how quickly value can be created from information.

📅 Timeliness: The timeliness of information determines how well the information matches the optimal timing of the actions. Having the information at the right time to make the decision is important. The higher the timeliness, the more value can be created from the information.

For example, in the information-value loop, sensors can create data about the trucks' locations, and communicate it as soon as they reach their routes' halfway point. The platform can aggregate and analyze the data to update the dispatch schedules accordingly. This can lead to more adaptive and flexible actions than if the data was only available after the trucks have returned to the depot.

⏱ Latency: The latency of information determines how close the information is to the current state of the world. The lower the latency, the more value can be created from the information.

For example, in the information-value loop, sensors can create data about the trucks' locations, and communicate it with minimal delay. The platform can aggregate and analyze the data to provide the most recent and relevant information about the trucks' progress, traffic, and ETA. This can lead to more accurate and timely actions than if the system was designed to only show information about the situation how it was 20 minutes ago, and the user needs to wait for an update.

Non-connected IoT?

With all of the previous knowledge about the information-value loop and the definition of IoT solutions one might wonder if something can be considered IoT or not.

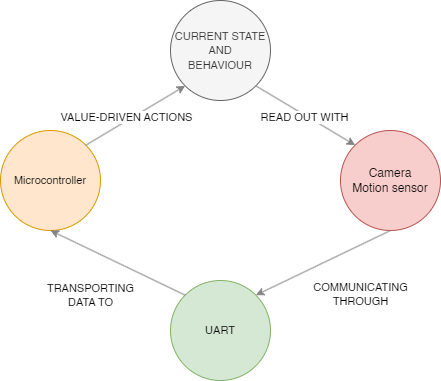

To make this question more clear we can think about a camera trap.

A camera trap is a device that automatically takes pictures or videos of animals when they pass by it. It is usually placed in a remote or hidden location, such as a tree or a bush, to observe wildlife without disturbing them. Camera traps are useful for studying animal behavior, population, and distribution, as well as for conservation and anti-poaching efforts.

Before concluding if this is considered IoT or not we can try to apply the information-value loop steps to a camera trap to spot wildlife:

- Sensors: The camera trap has a camera and a motion sensor that detect the presence and movement of animals in the vicinity. The camera captures images or videos of the animals, while the motion sensor triggers the camera to start recording. These sensors generate data about the physical event of wildlife spotting.

- Embedded communication protocols: The camera trap uses UART to communicate between the microcontroller, the camera, the motion sensor, and the memory card that are part of the embedded system. These protocols enable fast and reliable data transfer within the device.

- Embedded platforms: The camera trap has a microcontroller that acts as an embedded platform. It can communicate with the camera and the motion sensor using the embedded communication protocols. It can also process and store the image or video data on the memory card. The memory card can be removed from the camera trap and connected to a computer to view the contents of the platform.

Setting this camera trap in the information-value loop helps with getting a clearer picture of how components interact to deliver the value of a camera trap. But it also shows that this might not be considered IoT.

In the end this depends on the specific features and functions of the camera trap. A more precise way to phrase the question would be: “Does this camera trap have network connectivity, data sharing and digital-physical integration capabilities that qualify it as an IoT device?”

As this camera trap is not connected to a network to start off with it would not fit in the definition of being an IoT device.